Applications

Precisely control flow, especially be used for various kinds of dispensers of liquefied petroleum gas,

gasoline and diesel.

Construction

The valve has four states:

1.When the No.1/No.2 coil power is cut, main valve and auxiliary valve are both closed and flow

rate is zero.

2.The No.1 coil power is cut and the No.2 coil power is open, mail valve is closed and auxiliary

is open, the flow rate is tiny.

3.The No.1 coil power is open and the No.2 coil power is cut off, mail valve is open and auxiliary

valve is closed. the flow rate is normal.

4.The No.1/No.2 coil is opened, main valve and auxiliary valve are both opened, the flow rate is

transnormal.

Features

1.It is coupled pilot with direct valve and realizing control fluid.

2.High control accuracy, open and closed are classification.

3.Prevent water hammer from producing.

4.High reliability and long life.

5.Protective safety, little volume, style appearance.

6.Coil can self-protect when it supercurrent and superheat.

Technical specification

|

Item

|

Parameter

|

|

Orifice size (mm)

|

15

|

20

|

25

|

|

Power voltage (V)

|

AC220 DC24 Other voltages are available on request.

|

|

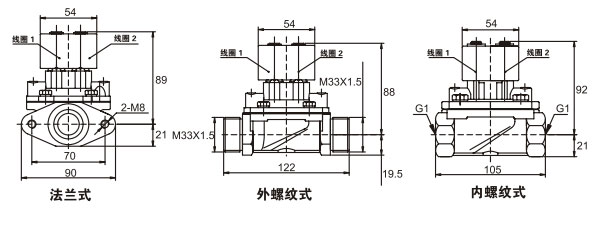

Type of connection

|

Female thread male thread flange

|

|

Operating differentialpressure (MPa)

|

0.02~0.3

|

|

Medium Temp. (℃ )

|

-20~60 -55~150

|

|

Ambient temperature (℃)

|

-25~60 -40~60

|

|

Relative humidity

|

≤95%

|

|

Insulation strength (MΩ)

|

≥20

|

|

Explosion-proof marking

|

ExmⅡT4

|

|

Max.Temp.of explosion proof shell (℃)

|

T4: 135 T3: 200

|

|

Grade of protection

|

IP65

|

|

Medium

|

Gasoline, diesel oil, LPG, gas, water, air

|

|